How to use threaded inserts ?

Overview

Threaded inserts allow you to add durable, reusable metal threads to your 3D printed parts. This is essential for parts that need to be assembled/disassembled multiple times, or where strong screw connections are needed.

Note that threaded insert is a good solution but not the only one. A good practice is also to have a pocket in your design where you can simply put a nut inside.

This tutorial covers the process for heat-set threaded inserts and includes both design and installation instructions.

Step 1: Design the Hole in your CAD model

- While modeling your part, design a hole at the insert location.

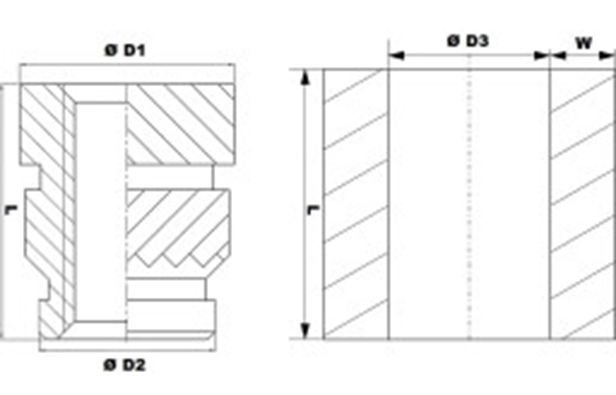

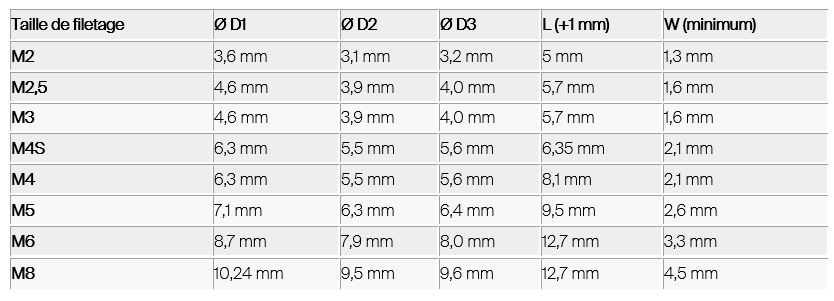

- Use the exact hole dimensions provided by the insert manufacturer, like hole diameter (D3), depth (L) and minimal wall thickness (W) around the hole.

Tips:

- Take some margin with the depth (at least 1mm more than the value)

- Add a chamfer to help guide the insert in smoothly (0.3~0.5 mm)

Step 2: Print your part and check the hole fit

- Once printed, try placing the smooth end of the insert (D2) into the hole by hand.

- If it doesn't fit: Don’t force it! Ask your mechanical workshop coach for help using a precision drill bit to correct the hole diameter.

PET-G can shrink slightly after printing, so minor post-processing is normal.

Step 3: Place the insert by hand

- Place the insert manually into the hole, starting with the smaller and smooth diameter end (D2).

- It should sit snugly but not be forced in.

- It only needs to start in the hole, not go all the way in — the heat will do the rest.

Step 4: Prepare the insert tool

- Choose the correct tip size for your insert.

- Mount the tip on your insert placement tool (while cold!).

- Set the temperature to the printing temp of your filament: 230 °C for PET-G

Warning: This tool gets very hot. Always place it back on its stand when not in use.

Step 5: Heat-set the insert

- Hold the heated tool vertically and gently press the insert.

- Apply light, even pressure.

- As the plastic heats up, the insert will begin to sink into the part.

Tips: Don’t force it — let heat do the work.

Keep the axis straight to avoid misalignment.

Watch the sides of the part — if it starts to bulge, stop. You may be overheating or pressing too hard.

Step 6: Make it flush

- Once the insert is fully seated, you can use a flat metal tool to gently press it down, ensuring it's flush with the surface of the part.

- This step helps with cosmetic finish and mechanical alignment.

You're Done!

- Turn off your tool and let it cool down safely.

- Don’t touch the metal tip — it remains hot for several minutes.

👏 Your insert is now permanently embedded and ready for screws! Don’t overtighten screws — inserts are strong, but the surrounding plastic can still deform.