The project of filament recycling

Sustainability is important to us. That's why your 3D printing coach has a sustainability program that focuses on the following key areas:

- Equipments:

Our printers are manufactured in Europe independently and sustainably. They are designed to have a long lifespan (no planned obsolescence, robustness, repairability, possibility to upgrade)

- Consumables:

Our standard PETG filaments are made from waste, offering the lowest impact on the market without compromising performance.

- Training:

By constantly improving student training, students make fewer mistakes. This drastically reduces the number of iterations needed to get prototypes working, resulting in fewer printjobs and less energy and material used.

- Recycling:

With more than 400 kg of plastic filament printed per year, it is estimated that between 20 and 30 kg of waste is generated annually in the 3D printing room. This waste consists mainly of printing supports and parts that do not work or are no longer useful.

Our PETG waste has been stored since the SPOT opened with a view to being recycled into new 3D printing filaments.

With the help of several successive semester projects, we have now succeeded in creating our own internal recycling process.

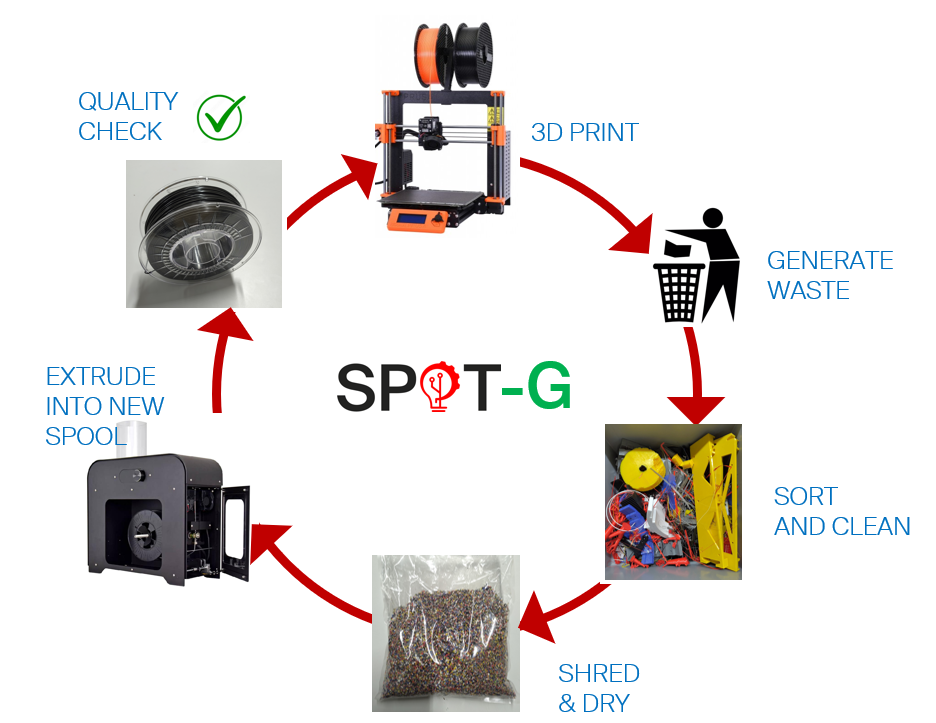

This process is as follows:

Results

- Sorting and cleaning the waste are critical steps in order to reduce the difficulties and number of defects at the end.

- Extruding a new filament from waste is particularly difficult, especially with PETG. The process is very sensitive.

- At the end, we are able to extrude good filament made 100% of waste (without adding virgin material) and with no loss of material properties!

- Because of all these factors, our spools still present some defects (diameter change, presence of foreign objects) that can clog the 3D printers' nozzles.

- Now we are working on quality control: detection and correction of the defect.

The project is still in progress but hopefully we will be able to let students try our in-house filament in 2026.

How you can contribute

- As a SPOT user, you already contribute by giving us some raw material. But PLEASE, throw your plastic parts carefully! PURE PET-G ONLY!! NO GLUE; NO SCREWS, NO INSERTS!!

- As a Master student, you can contribute by doing a semester project with us! Ask the coach for available projects.

- You can also join the Plast it back group of students who is focusing on plastic recycling.

Printing with SPOT-G

During the test phase, you can print with SPOT-G on P33 MK4 printer. Please print only on this printer!

Settings you need:

- Printer: MK4 Input Shaper with 0.4 mm nozzle

- Filament: SPOT PETG – MK4IS

See the wiki page for PrusaSlicer configuration SPOT configuration for PrusaSlicer

Please read carefully:

- This filament is in beta-test mode. For short and non-decisive parts ONLY!

- The filament might get stuck in the printhead from time to time.

When this happens, the printer will pause and unload the filament. Cut the defect*, reload the filament and resume your print.

- Print during the day and stay here to be able to do the correction.

- Please give us your feedback on the sheet next to the printer so we can monitor defects frequency.

* Defects types

The filament will get stuck and stop printing if its diameter exceeds 2mm. You can have two types of defects on this filament:

- Short defect: when there is a foreign object inside (shredded insert for example). In that case, cutting 2 or 3cm of filament should be enough.

- Long defect: when diameter is just too large for more than 2cm. In that case, you might have to cut a longer portion of the filament, until it get loaded in the nozzle again).